On the occasion of its 30th anniversary, we extend our sincere congratulations to the stakeholders and partners of the University, and to the trade and production group of companies, Textile-Contact.

Despite martial law, ongoing shelling, economic challenges, and other difficulties, TK-Domashniy Tekstyl LLC, part of the Textile-Contact Group and one of the largest home textile manufacturers in Ukraine, remains resilient, professional, and adaptable. The company continues to operate and grow daily – introducing innovative equipment, creating new jobs, enhancing its production processes, and striving for continuous improvement.

The company is developing dynamically across various sectors, actively participating in international tenders organized by both Ukrainian and global charitable organizations, and steadily advancing toward new achievements and partnerships worldwide. “It is extremely challenging to secure the necessary funds, resources, and personnel to implement such investment projects. However, these efforts not only expand our company’s capacity and capabilities but also contribute to sustaining the Ukrainian economy”, said Volodymyr Martsenyuk, Managing Partner of TK-Domashniy Tekstyl, in an interview.

On March 27, 2025, students of the first (bachelor’s) level of higher education under the educational programs “Modelling, Design and Artistic Decoration of Light Industry Products”, “Design and Technology of Garments”, “Fashion Industry”, specialty G15 “Light Industry Technologies”, visited TK-Domashniy Tekstyl LLC, a stakeholder, and partner of KNUTD. The visit was initiated by the heads of the Faculty of Arts and Fashion for second- and third-year students of the Fashion and Style and Fashion Technology departments. Nataliia Ostapenko, Dean of the Faculty of Arts and Fashion; Tetiana Struminska, Head of the Department of Fashion and Style; and Tetiana Dzykovych, Associate Professor of the Department of Fashion Technology, accompanied the students.

Natalia Aminova, Head of the HR Department, welcomed the visitors and gave them a tour of the enterprise. She introduced the facilities, explained the specifics of the company’s operations and product range, and presented the materials used in production. The visit provided students with valuable insights into production organization, stages of home textile and clothing manufacturing, as well as the equipment and tools involved in the process.

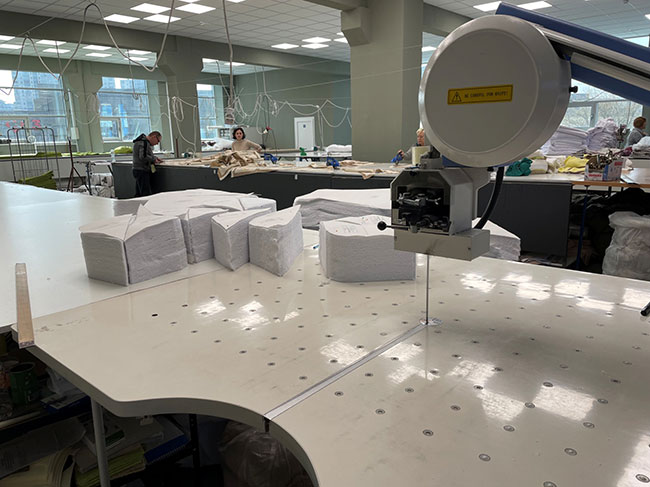

The attendees watched the work of a new modern ultrasonic soldering and cutting line, which quilts up to 2000 meters of fabric per day, has more than 500 ultrasonic soldering patterns, and joins up to three layers.

The visit to the knitting workshop, now located in its new premises, was especially informative. The students observed with great interest the operation of industrial knitting, winding, treadle machines, and ironing tables used for steaming knitted products – all sourced from leading manufacturers in Japan, Italy, and Turkey. They were particularly enthusiastic about exploring the collection of soft, elastic, and body-friendly knitted sweaters, hats, scarves, and blankets in fashionable colors.

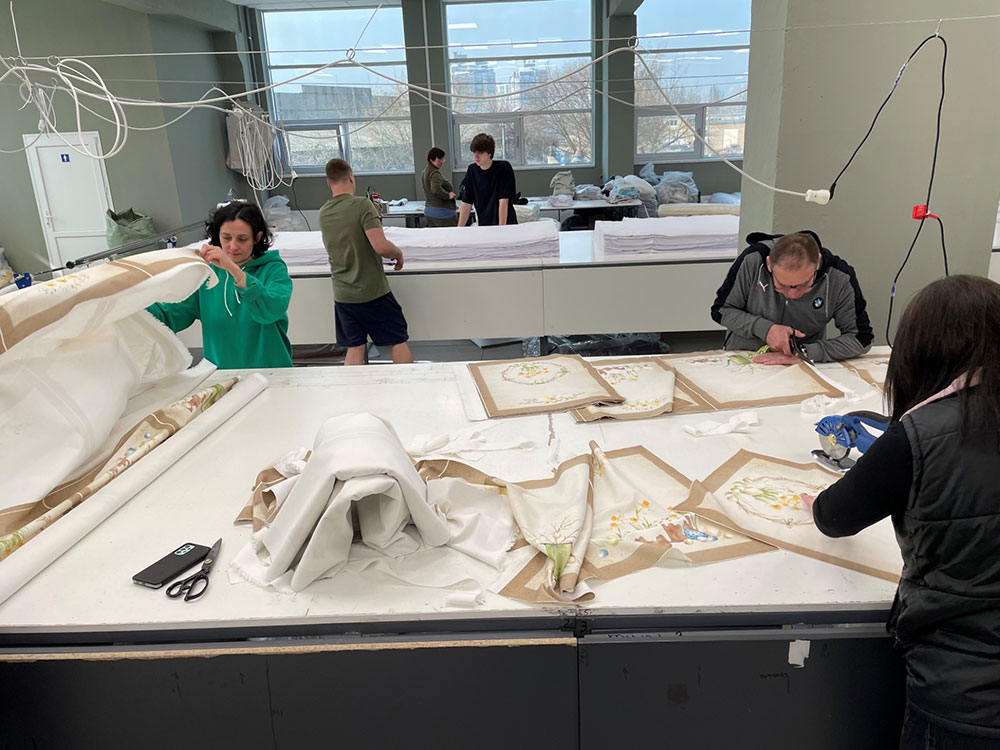

The students also visited the cutting workshop, where they became acquainted with its workflow and observed various types of spreading tables, mobile disc cutters, straight-knife cutting machines, and band-knife machines used for making precise cuts. They gained insight into the principles of the cutting process and had the opportunity to watch flooring and cutting operators at work.

The students were impressed by the scale of the company’s operations, the organization of the production process, and the variety of innovative equipment and machinery. They were also interested in the range of products, as well as the employees’ attitude to their work, the product they produce, and the warm attitude of the management to the employees.

The university students showed great interest in the company’s operations, unique features, and available job opportunities. They gained valuable professional insights, hands-on experience, and strong motivation to further develop their skills in the textile industry. The creativity embedded in the company’s products also served as a source of inspiration.

The company’s doors are always open to talented university students. The management of the company actively engages students from Kyiv National University of Technologies and Design in the production process, providing them with training and the opportunity to become part of a friendly and professional team.

We sincerely thank the company’s management and staff for their warm hospitality, the chance to explore the impressive production facilities, and meaningful interaction with experienced professionals at various stages of the manufacturing process.

We extend our heartfelt appreciation to our stakeholders for their reliable partnership, dedication, hard work, and professional approach. Your commitment deserves the highest recognition. We wish you strength, continued success, and creative accomplishments.

We also express our deepest gratitude to the Armed Forces of Ukraine for making it possible for us to work, learn, and grow.

09.04.2025