Cooperation between industry and higher education institutions is a vital component of modern economic development. It supports the training of highly qualified specialists, provides students with valuable practical experience, and offers businesses access to fresh ideas, innovative solutions, and potential employees who meet the evolving demands of the labor market.

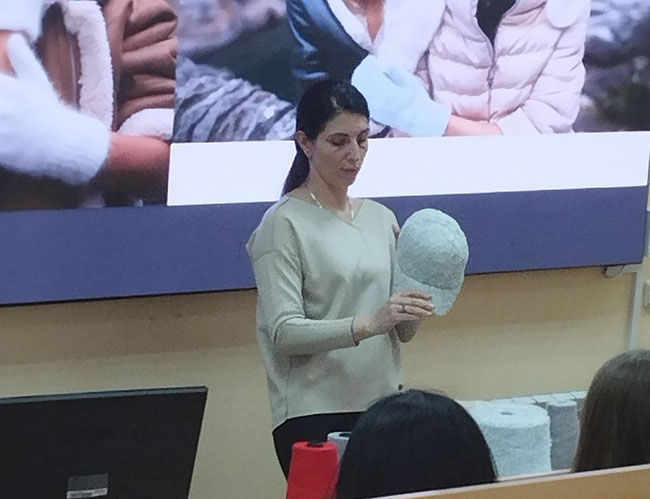

As part of Career Day, held on May 6, 2025, representatives of the “Odyssey” company visited the University: Lina Alatorskykh, Production Manager, and Yuliia Ikonnikova, HR Director. The company specializes in the production of women’s headwear, including hats, caps, and bonnets, as well as matching accessories such as scarves, mittens, and gloves. Its main production facilities are located in Brovary, with an experimental workshop operating in Kyiv.

“Odyssey” has been successfully operating in the market for over 22 years, producing goods in the upper mid-price segment. Annually, the company manufactures between 800,000 and 1.2 million units of products and develops from 300 to 1,500 new models. Its product color range includes up to 115 shades within a single line. Items made from roll materials and fur constitute approximately 10% of the overall assortment.

The company began its operations in 2012 with a single knitting machine. Today, it operates nearly 55 units of advanced industrial high-tech knitting equipment from the Japanese brand Shima Seiki, along with approximately 70 sewing machines. The company utilizes knitting machines ranging from class 1 to class 14, allowing for the production of a wide variety of items – from heavy outerwear to fine knitwear of varying complexity.

Production at the enterprise is organized along a conveyor line – from initial manufacturing to final shipment – with multi-level quality control implemented at every stage. The company maintains a full-cycle production process, which includes equipment cleaning, maintenance, and repair. Additionally, it operates a wet-heat treatment workshop, where garments undergo chemical washing and steaming to ensure a market-ready appearance.

The company currently employs 132 full-time people, including designers, engineers, knitters, programmers, laundry operators, garment and knitwear technologists, finishers, and other specialists. In addition, more than 50 home-based workers are involved in the production process. Plans are also underway to launch a dyeing workshop for both raw materials and finished knitted products.

The company’s primary suppliers of raw materials are based in Italy, Turkey, and China. The yarns used consist mainly of natural fibers, including wool, angora, alpaca, mohair, and cotton. Acrylic is used in limited quantities and only of high quality. All raw materials are certified – many bearing the prestigious “Woolmark” certification – and are subjected to laboratory testing. Finished products undergo trial wear testing to ensure quality and durability.

Thanks to innovative solutions and optimized production processes, the company successfully scaled up its operations and restored production volumes to pre-war 2021 levels, despite a temporary decline in 2024 due to wartime challenges. “Odyssey” maintains active cooperation with the University by offering students industrial and pre-graduation internships, organizing facility tours, hosting introductory meetings with specialists, and exploring future employment opportunities for graduates.

The core values of the company are quality, innovation, and responsibility. “Odyssey” is committed to meeting consumer needs by delivering products that adhere to the highest quality standards.

We sincerely thank the representatives of “Odyssey” for a meaningful and productive meeting!

12.05.2025