Three times - оn May 20-28 and June 3, 2025, the main production facilities of ODYSSEY in Brovary were visited by students of the first (bachelor’s) level of higher education majoring in G15 “Consumer Industry Technologies” under the educational programs “Modelling, Design and Artistic Decoration of Consumer Industry Products”, “Fashion Industry” and “Design and Technology of Garments”, accompanied by Natalia Ostapenko, Dean of the Faculty of Arts and Fashion; Tetiana Strumynska, Head of the Department of Fashion and Style; Tetiana Dzykovych, Associate Professor of the Department of Fashion Technology; Svitlana Lozenko, Senior Lecturer of the Department of Fashion and Style.

The students and teachers were hospitably welcomed by Lina Alatorskykh, Production Manager, and Yulia Ikonnikova, HR Director and given a comprehensive tour.

Lina Alatorskykh spoke about the knitwear company, introduced the visitors to the range of products and technological transitions and the full cycle of knitwear production, from the manufacture of knitted fabric to the sewing of finished products.

The ODYSSEY company was founded in 2012, marking the beginning of its journey in the world of business and innovation. Today, the company is one of the largest producers of high-quality knitted hats and accessories in Ukraine, whose products are successfully sold both in the domestic market and in many European countries.

At the initial stage, the future specialists visited the marketing and sales department, where they had a detailed look at the company’s wide range of products. The company’s production facilities manufacture women’s berets, hats, caps, as well as children’s hats, snoods and scarves from a variety of yarns, mostly natural, including wool, angora, alpaca and cashmere. The company also offers sewn hats made of fabrics.

The tour participants then went through all the key stages of production, which provided a comprehensive understanding of the knitwear manufacturing process. The visit to the yarn warehouse gave the students an understanding of the processes of unpacking and storing the raw material supplied by suppliers, and provided them with knowledge of qualitative and quantitative methods of controlling raw materials, which are the basis for future products.

At the yarn rewinding area, the students got acquainted with the technology of preparing yarn for further knitting, with the equipment for twisting yarn into the required number of threads of a given colour scheme and the possibility of fulfilling an individual order for yarn of various compositions with sequins, beads and other decorations on one cone and equipment for rewinding yarn from the torn fabrics from the machines.

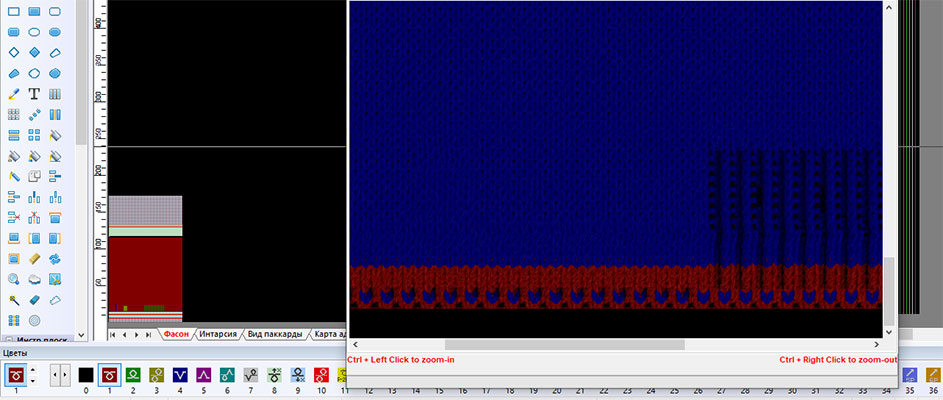

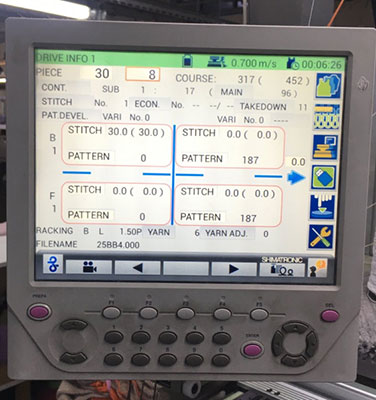

In the knitting shop the students watched with interest the work of a desinator, a technologist and a knitting machine operator. The production facilities of the enterprise are equipped with modern computerised flat knitting machines from the Japanese company Shima Seiki in the amount of more than 50 units of the 1st and 14th classes, which allows creating knitted fabrics and semi-finished products of various weaves and designs of specified shapes.

The visit to the technological department, equipped with modern computers and specialised software, highlighted the role of innovation in optimising production processes and developing new models.

The visit to the knitting department demonstrated the capabilities of knitting machines of different classes and highlighted the importance of quality control at every stage of production.

At the semi-finished product moisture and heat treatment area, the students learnt about the technologies for washing, drying, fluffing and moulding products during the manufacturing process. The company uses modern means to clean semi-finished products and give them the necessary volume and softness.

The students also watched the process of ironing and steaming of product parts, which is necessary to improve the shape and stabilise the loop structure of knitted fabrics and products.

Then, the participants of the tour had the opportunity to see the process of cutting semi-finished products according to patterns.

In the sewing shop, students watched semi-finished products being sewn together using a thread method on universal and special sewing machines.

The attendees were interested to see the work of professionals on the ketel machines and the area of forming the upper part of the hats, which is an important part of the production of hats.

Observation of the work of specialists in finishing, quality control of finished products, picking and packing made it possible to learn about the stages of steaming products to stabilise their shape and give them a marketable appearance, quality control and preparation of finished products for shipment to the customer.

The inspection of the finished product warehouse allowed them to see the final stage of the production cycle and understand the production process.

During the tour, the students had the opportunity not only to see but also to feel the dynamics of modern production, which is equipped with advanced equipment and operates using innovative technologies. The students deepened their knowledge of the stages of knitwear creation from idea to production. The tour also helped to expand the knowledge of higher education students in the framework of the work of the student research clubs “Creative Design and Innovative Technologies for the Manufacture of Garments” and “Textiles in Interior and Fashion”.

We express our deepest respect and sincere gratitude to Lina Alatorskykh, Yulia Ikonnikova and the entire «Odyssey» team for their hospitality and the unique opportunity to visit a modern, powerful enterprise. This experience allowed our students not only to consolidate the theoretical knowledge acquired during their studies, but also to significantly broaden their professional horizons and deepen their professional competencies. We look forward to further fruitful cooperation!

19.06.2025