RESEARCH AREAS

– research of physico-chemical patterns of production and modification of fibrous materials with special properties;

– creation of new fibrous composite materials containing natural polymers and eco-friendly fillers, and research of their properties;

– research on the morphology and rheology of polymer composite materials.

ACTIVITIES

Educational:

Carrying out of the laboratory work and scientific research by students, masters and postgraduates in specialty 161 - "chemical technologies and engineering".

Research:

- Physicochemical regularities of obtaining microfibers filled with nano-sized additives.

- Creation of new composite materials containing natural polymers and study of their properties.

- Microscopic studies of polymer composite and fibrous materials of various compositions.

- Rheological studies of fiber-forming polymer solutions filled with various types of additives.

- Development of technology for obtaining fibrous materials by electroforming.

- Establishment of structural changes in composite materials containing biopolymers during their preparation and biodegradation.

- Study of electroforming processes of micro- and nano-fibrous bioactive materials for special purposes.

- Establishment of the relationship between morphological indicators of various types of polymer compositions with their composition and physical and mechanical characteristics.

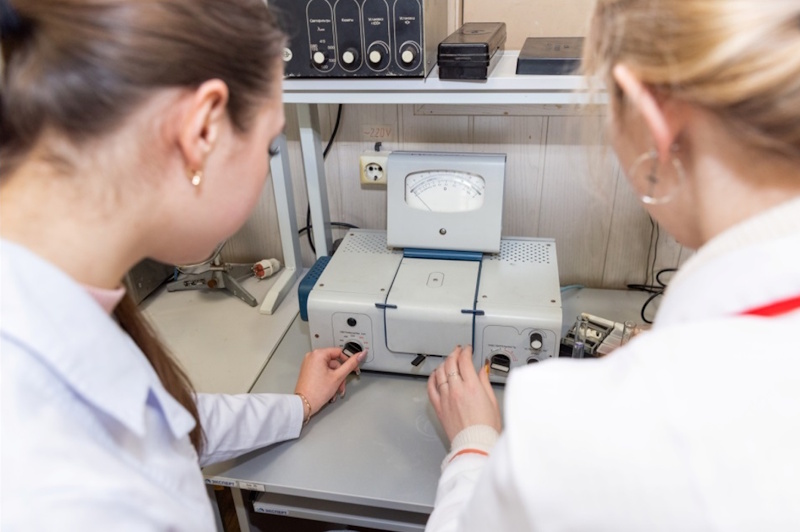

LABORATORY EQUIPMENT

- Experimental and industrial spinning extrusion machine.

- Experimental installation for obtaining fibers by electrospinning.

- Combined worm-disk extruder, LGP-25.

- Worm extruder, ChP-45.

- Optical microscope brand MBD.

- Polarizing microscope MBI-15.

- Optical microscope brand Biolam.

- Polarizing microscope, MP-8, equipped with a digital nozzle.

- Analytical balance brand TORSYJNA-WT (with an accuracy of up to 5 digits).

- Rewinding machine Polykon.

- Stand for thermal orientation drawing of fibers.

- Ultramicrotome.

- Tearing machines, RM-30, RM-3, RM-250.

- Vacuum drying cabinet.

- Microviscosimeter MV-2.

- Crushing plant for obtaining polymer granules.

- Laboratory carding machine.

- Fiber stapling unit.

PAID SERVICES

- development of technologies for obtaining fibers and fibrous materials with special properties (biodegradable, chemisorption, ultrafiltration, nanofilled, antimicrobial, medical);

- physical and mechanical complex analysis of polymer composite, fibrous, and nanofilled materials;

- advanced training of specialists working in the field of processing polymer composite, fibrous, and nanofilled materials.

PHOTOS OF THE LABORATORY